- Homepage

- Artist / Writer

- Genre

- Action (32)

- Action / Adventure (19)

- Action, Adventure (11)

- Action, Horror (4)

- Adventure (2)

- Bad Girl (3)

- Comics (10)

- Games (2)

- Ghosts (37)

- Horror (91)

- Horror & Sci-fi (369)

- Monster (5)

- Movie & Tv (13)

- Mystery (2)

- Superheroes (66)

- Tv & Movies (5)

- Tv Horror (3)

- Tv Shows (3)

- War (12)

- Zombie (12)

- Other (2910)

- Issue Number

- Series Title

- 10th Muse (2)

- Book Of The Dead (3)

- Darth Vader (3)

- Dc Comics Presents (5)

- Giants (2)

- Infinity (3)

- Menace (2)

- Negan Lives! (2)

- Peyton Blue \ (2)

- Skybound X (3)

- Spawn (4)

- Spider-man (2)

- Stray Dogs (3)

- The Walking Dead (551)

- Volume 1 (2)

- Walking Dead (197)

- Walking Dead Deluxe (4)

- Walking Dead Pooh (5)

- Walking Dead Weekly (4)

- Zombie (3)

- Other (2809)

- Unit Of Sale

- Universe

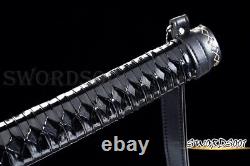

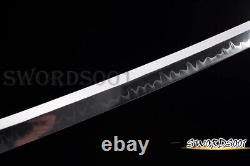

Handmade Walking Dead Sword Japanese Samurai Katana T10 Steel Clay Tempering

Handmade Walking Dead Sword Japanese Samurai Katana T10 Steel Clay Tempering. Historically, katana was one of the traditionally made Japanese swords that was used by the samurai of ancient and feudal Japan. The katana is characterized by its distinctive appearance: a curved, single-edged blade with a circular or squared guard and long grip to accommodate two hands.

Samurai katana as a weapon is famous for its beautiful shape. They are used as art collection and the symbol of samurai soul. Our sword allows you to make a collection or to send to friends as a present. The blade of this sword is made of. The high-performance blade has very good toughness and does not deform when bent at 90 degrees. The hardness is as high as 58. Cutting the wire does not hurt the blade. It can be used in battle or for display.We would highly recommend it as a gift. Anyone would be thrilled to receive a gorgeous sword as a gift!

Overall Length:103 cm/40.6 inch Blade Length:70 cm/27.6 inch Handle Length:26 cm/10.24 inch Blade Width:3.2 cm/1.26 inch Blade thickness:0.7 cm/0.28 inch Blade:T10 carbon steel, clay tempering, real hamon BLADE SHAPE: Shinogidukuri NAKAGO: full tang KISSAKI: medium (chkissaki). Tsuka:hard wooden core wrapped with imitated ray skin and black PU leather ito. The fuchi and kashira are made of zinc alloy.The handle is fixed by two menuki on two sides. Tusba: zinc alloy tsuba, used to protect your hand from sliding onto the blade during thrusts Nakago: full tang, which greatly enhances the strength of the sword Saya: wood scabbard wrapped with black PU leather belt. (No display stand and other fittings along with).

Before being quenched, a special clay mixture can be applied onto the blade to harden the edge and obtain different hardness on the blade. The clay mixture was a special recipe and considered a crucial trade secret, guarded protectively by sword making masters. It would contain such things as feathers, powdered bones, grass, etc. And would be applied to the edge of the blade before being quenched. During quenching, a chemical reaction between the clay mixture and the hot steel occurs during the sudden temperature drop and carbon is fed into the blade in high amounts, creating an extremely tough edge.

A clay hardened blade can only be quenched in water, thus increasing the defect rate even more. Another way for clay tempering is to apply clay along the blade but let edge exposed. Thus, while quenching the blade into water, the uncovered edge will cool down suddenly, but the rest of blade will cool down slowly. Such differential temperature change results in the different hardness of the blade.

So the edge is tough enough to cut, where the back of blade is soft /flexible enough to absorb the impact during cutting. Such quenching process usually will leave beautiful wavy tempered line on the blade, as known as "hamon" in Japanese swords term. International Buyers - Please Note. Please contact with us before you leave feedback.

We will try our best to solve the problem for you, thank you. Sometimes, you may not get our reply immediately due to the time difference among each country.

However, please be assured that we'll strive to reply you as soon as possible once we got your messages.